With Industry 4.0, automation has started to be seen as a compulsory need for businesses not only in the field but also in office processes. Automation is an investment process that not only reduces the human factor, but also should be considered by businesses in terms of speed, quality and sustainability. In terms of return on investment, it is seen that the rate of return on investment in automation in return for investment in human is quite high and measurable.

Although automation is understood today as the work done with human power by machines and programs, in fact, automation is the processes in which the processes are integrated, one after the other, and the human factor is minimal or zero. When you think of a factory that manufactures with automation, it may include the entire process from the raw materials coming from the warehouse to the production line, performing the necessary processes for manufacturing, packaging these productions and delivering them to the necessary shipping warehouses, even loading them into the shipping vehicles, even detecting the failures of all the equipment involved in this process and supplying the necessary equipment. . As an example of these enterprises, dark factories are the target of even small and medium-sized enterprises today. By examining all your processes from machine to software in terms of automation, we offer you the appropriate solutions and meet your needs as soon as possible with our turnkey projects.

Robotic manufacturing tracking applications facilitate your tracking from raw material to final product by marking and reading your products. For this purpose, you can achieve top-to-bottom traceability in your business with small investments.

We offer you the most suitable solutions by analyzing every single one of your processes, from infrastructure to design, from product selection to their implementation. You can get 24/7 support for the solutions we offer.

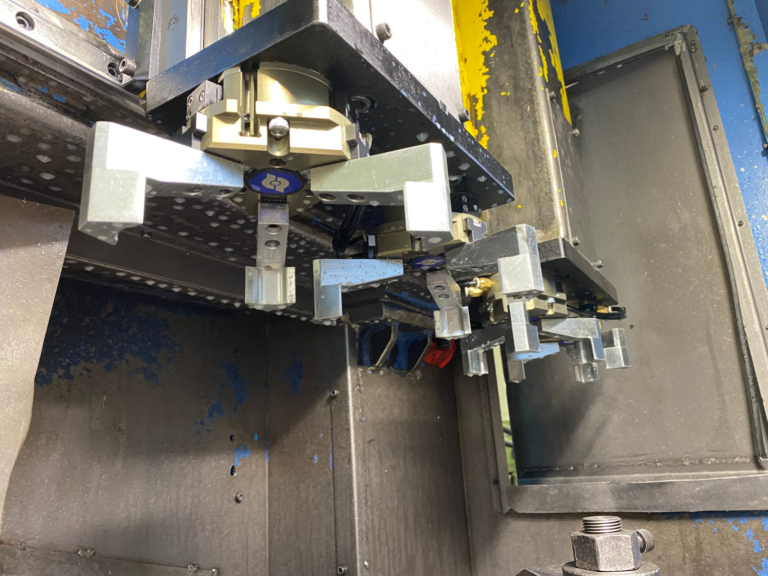

Manufacturing under human control in machining benches allows for errors. To prevent these, you can be one step ahead in quality with systems that can be integrated into your existing machines.

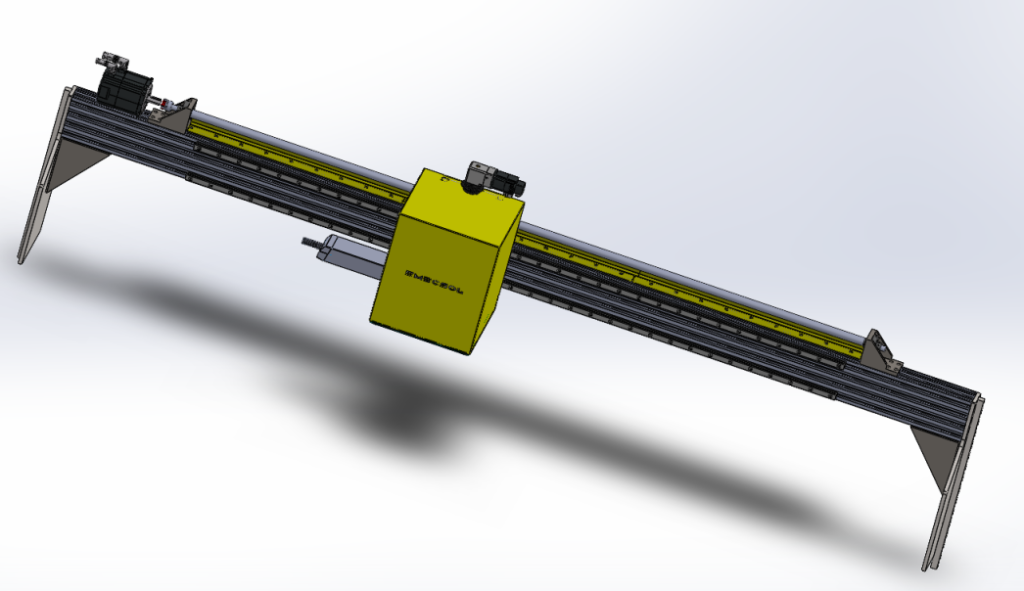

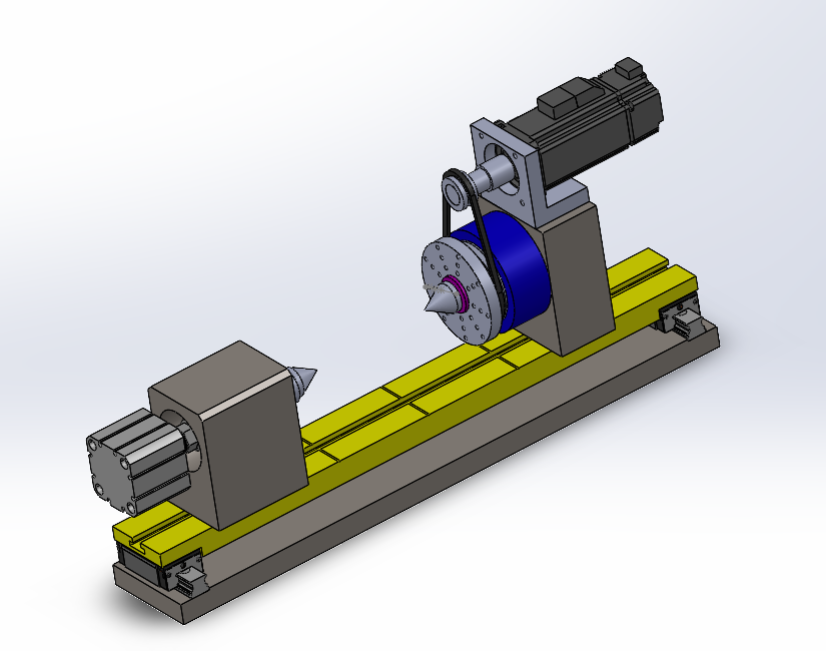

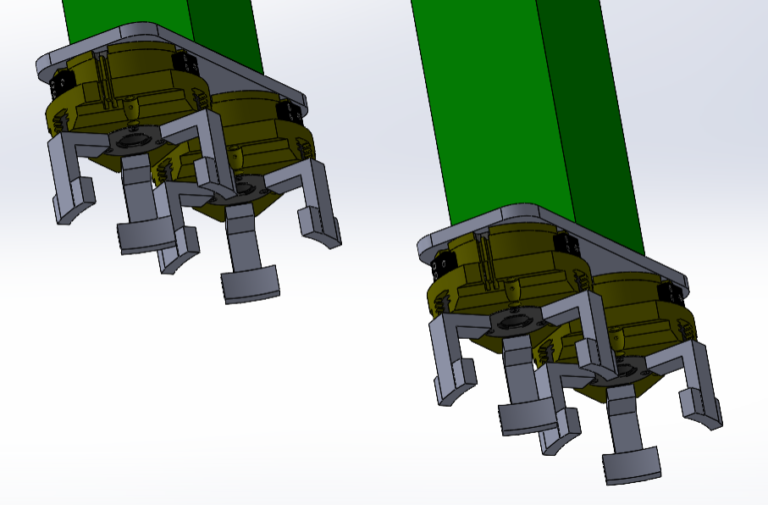

The time lost during loading and unloading operations on your existing benches can be increased up to 100% in terms of efficiency. For this, you can fully meet your needs with small solutions such as cartesian robots, conveyors, turntables and make full use of your production capacity.

During the control of your products, you can provide many controls such as color, size, size, burrs, holes with suitable fixtures or cameras for all situations that may escape the human eye.

In order to establish the connection between the production stations and to ensure the continuity of the process, we work for you for revisions and integrations in your existing machine park.

We offer you the most suitable solutions by analyzing every single one of your processes, from infrastructure to design, from product selection to their implementation. You can get 24/7 support for the solutions we offer.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie has been set by EMECSOL within the Scope of GDPR. The cookie is used to store user consent for cookies in the "Analytics" category. |

| cookielawinfo-checbox-functional | 11 months | The cookie is set with the cookie permission under the GPDR to save the user permission for cookies to the "Functional" category. |

| cookielawinfo-checbox-others | 11 months | This cookie has been set by EMECSOL within the Scope of GDPR. The cookie is used to store user consent for cookies in the "Other" category. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie has been set by EMECSOL within the Scope of GDPR. Cookies are used to store user consent for cookies in the "Required" category. |

| cookielawinfo-checkbox-performance | 11 months | This cookie has been set by EMECSOL within the scope of KVKK. The cookie is used to store user consent for cookies in the "Performance" category. |

| viewed_cookie_policy | 11 months | The cookie is set by EMECSOL within the scope of GDPR and is used to store whether the user allows the use of cookies. It does not store any personal data. |